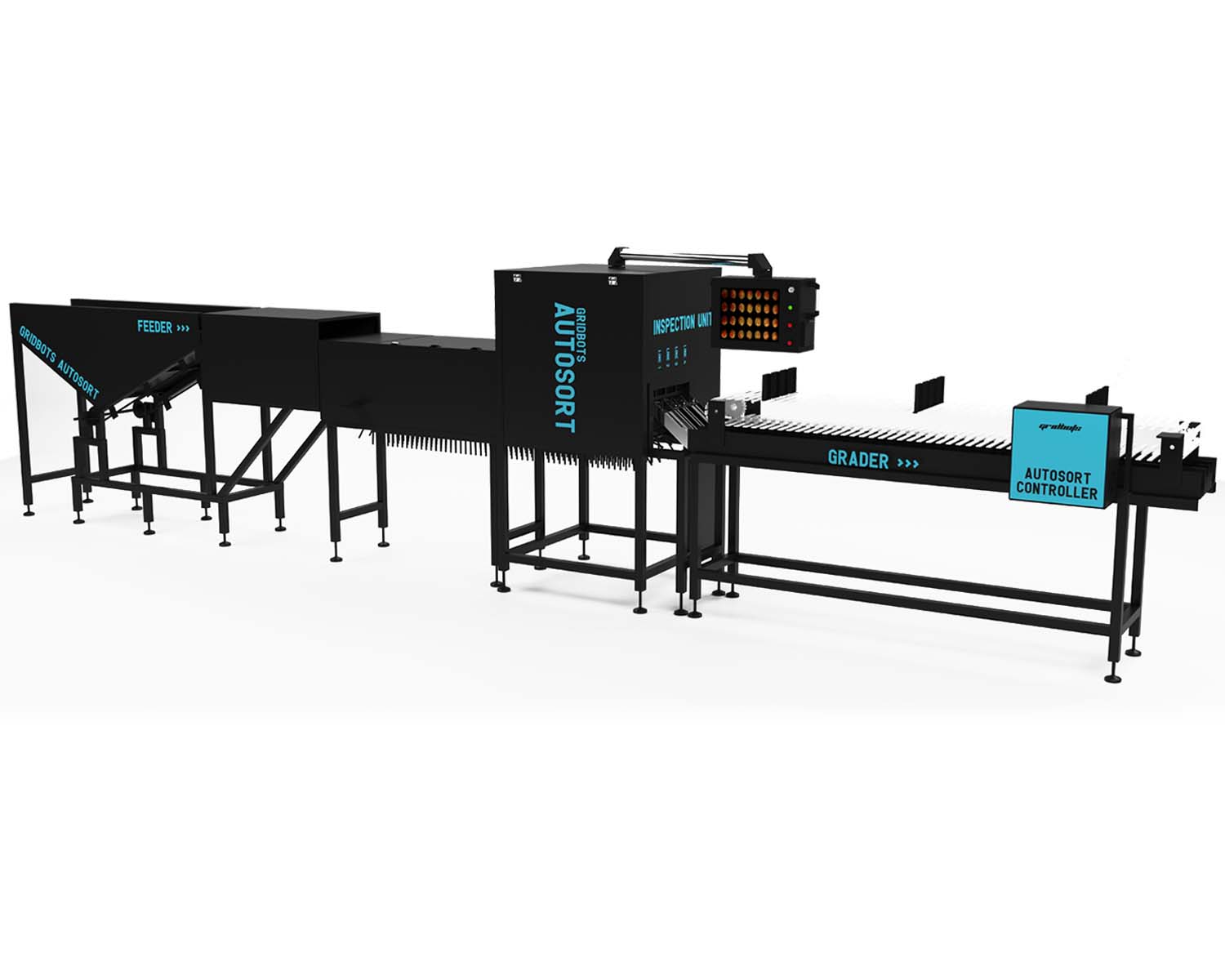

Gridbots Autosort

Sorting - Grading - iNSPECTION

Gridbots Autosort™ is a real-time 360 degree sorting and grading system which can sort upto 500,000 items per hour. AutoSort™ uses advanced machine vision algorithms to sort items like fruits, vegetables, cashews, potatoes, chips, French fries, potato flakes, dehydrated vegetables or Individual Quick Frozen (IQF) foods such as carrots or peas at very high speeds. It is one of the most cost effective solution for your sorting, grading applications. It can locate and identify foreign material, stones, metallic and non metallic items in the feed and can remove them explicitly. The system provided multi station and multi grade segregation options in the smallest pace and footprint. It uses Ultra high speed GPU compute units with high resolution cameras, 3D Scanning systems and hyperspectral sensors with Gridbots gridEYE™ computing software. This technology can rotate a round or cylindrical produce to detect defects at high speeds and remove them swiftly from the out feeds. It relieves you of manual sorting issues like low throughput inaccurate results, contamination possibilities due to human touch and space constraints.

HIGH SPEED SORTING - GRADING - INSPECTION