Gridbots BoxMatic

Automatic Box Cleaning and Inspection System

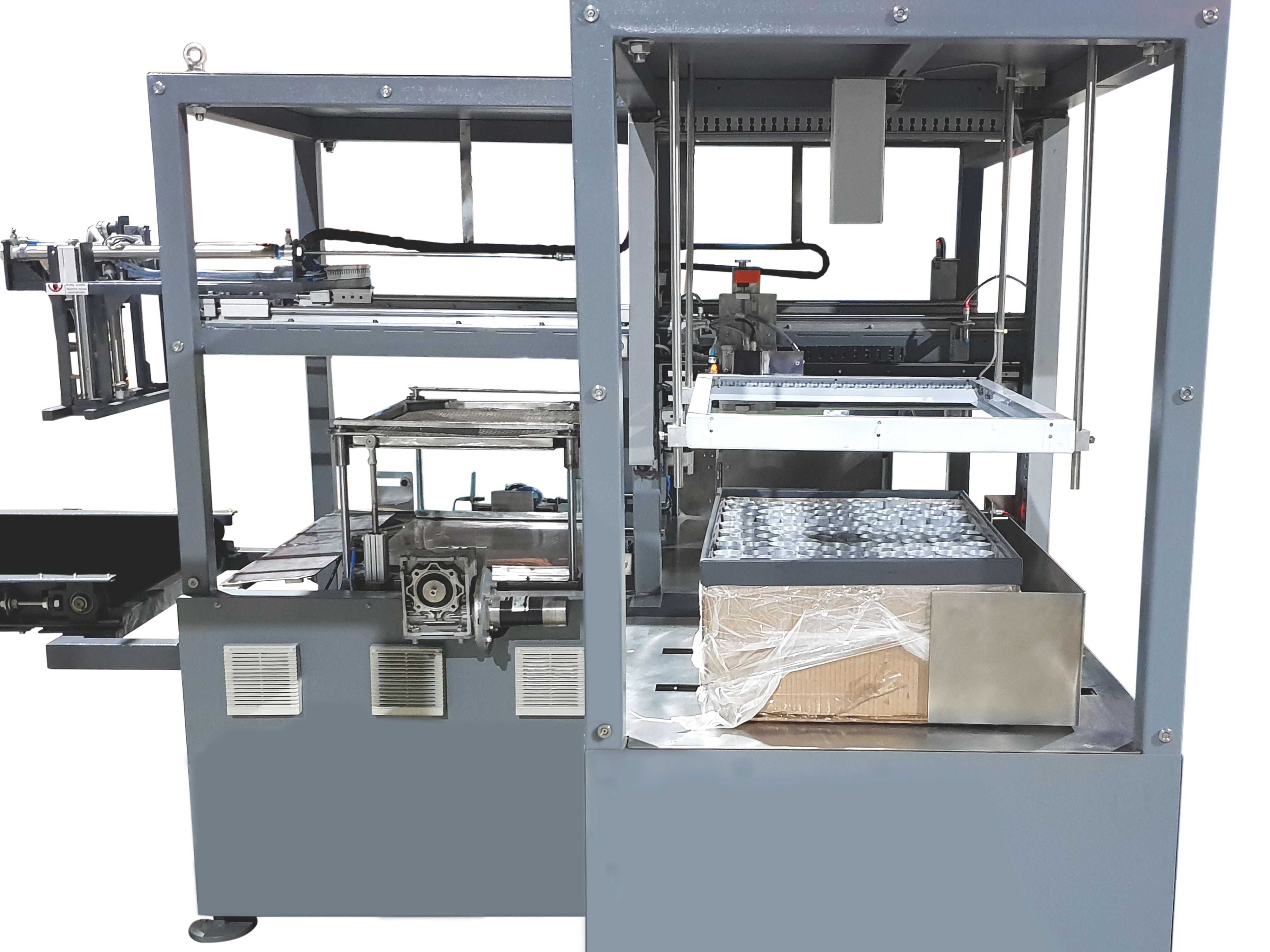

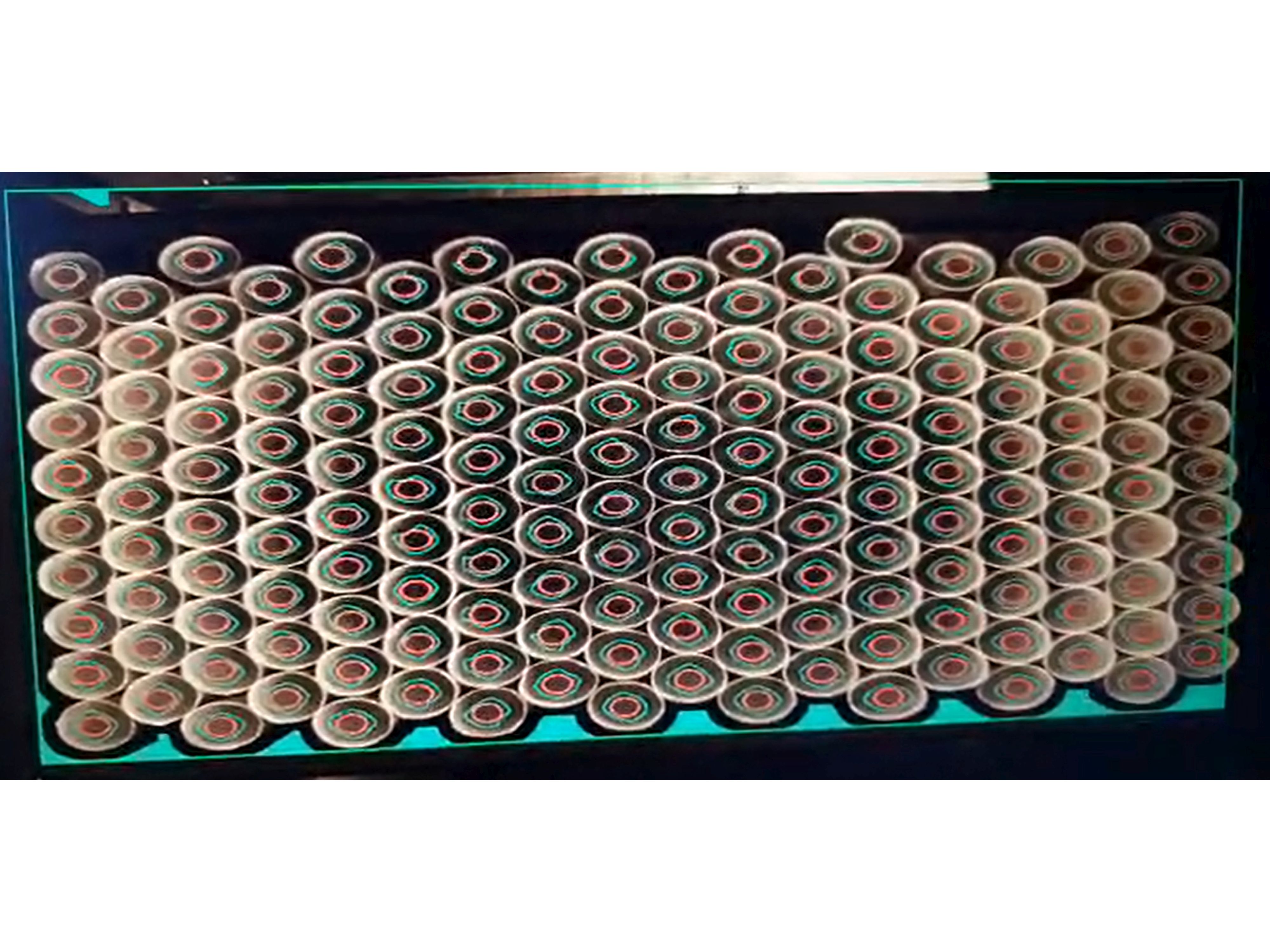

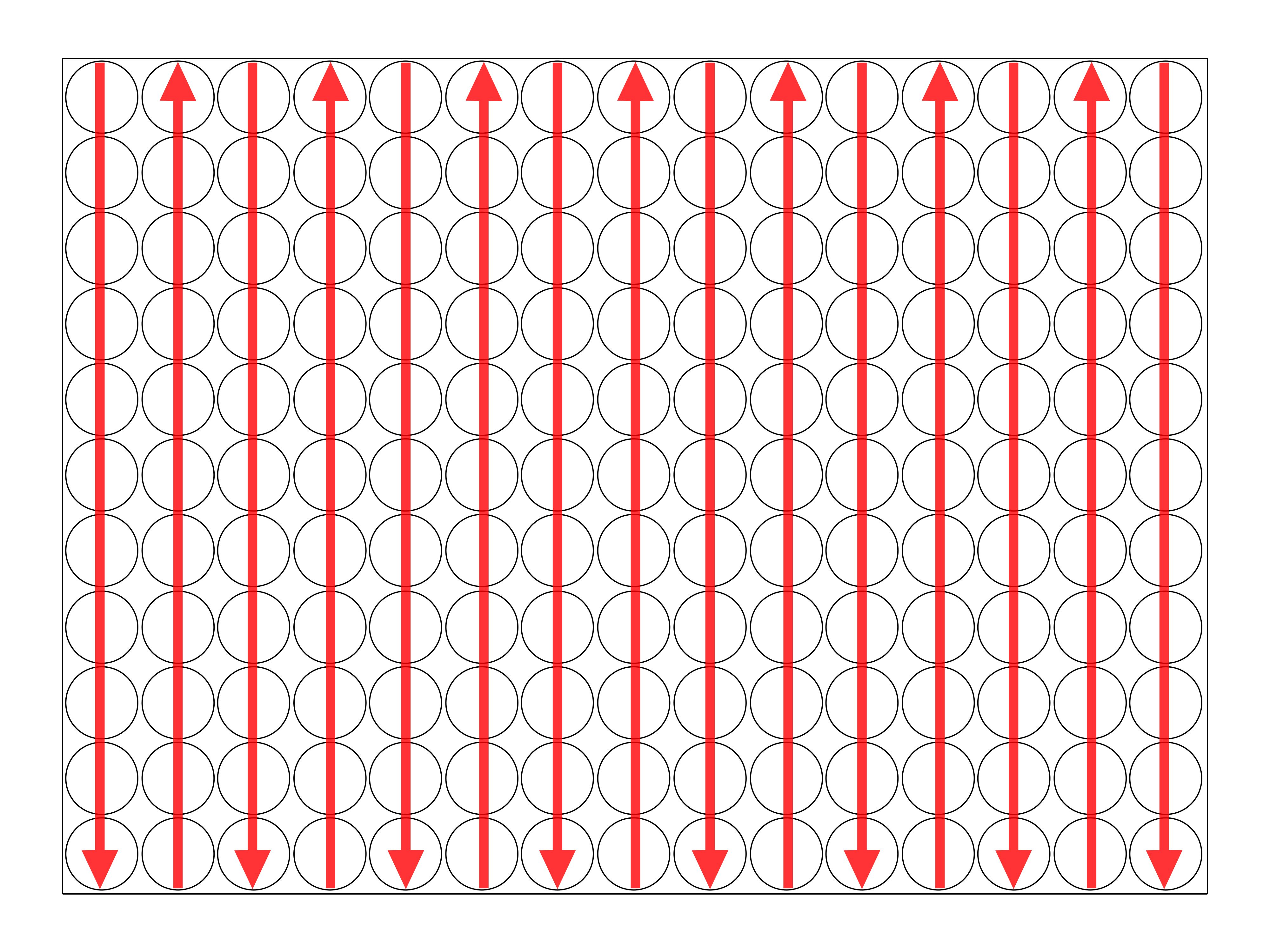

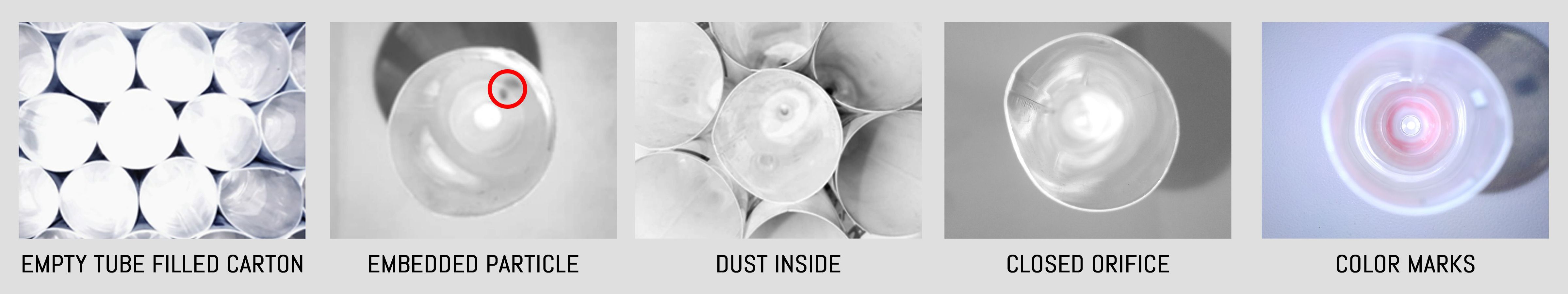

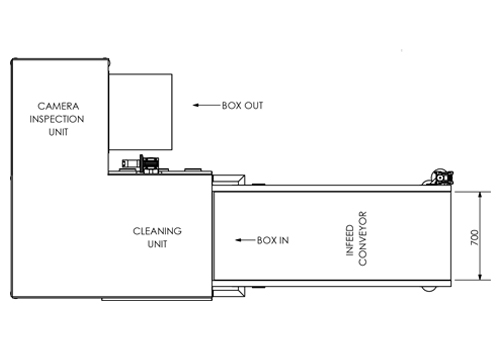

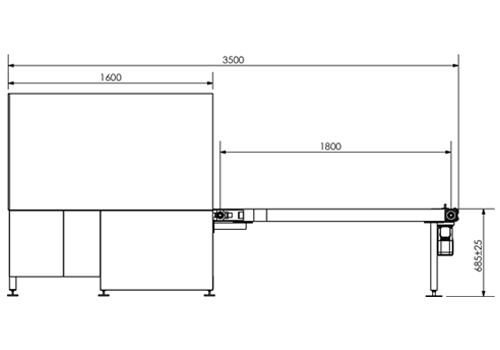

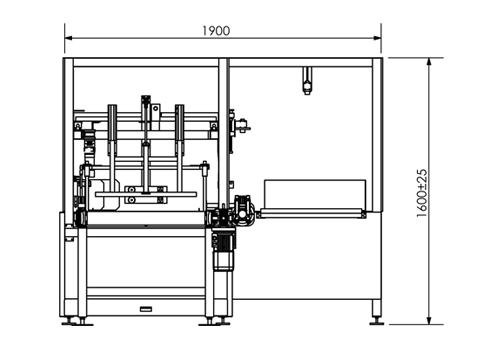

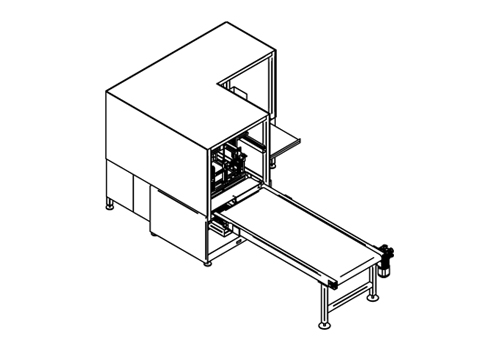

BOX Cleaning & Inspection System is a fully automatic machine for cleaning and inspection of empty tube filled cartons as shown below. First high pressure ionized air based cleaning is done, and then each tube is inspected for still remaining any black particle inside the tube using a camera. Other defects such as closed orifice or blocked orifice, color marks are also inspected. In current setup, operator needs to manually remove the faulty tube indicated by the laser highlighter. Lastly total tube count with no. of rows and columns is provided to the operator.

The system is installed after the filling of tubes has been done in the carton and now it can automatically inspect the carton from the top

AUTOMATIC BOX CLEANING AND INSPECTION