Panaview

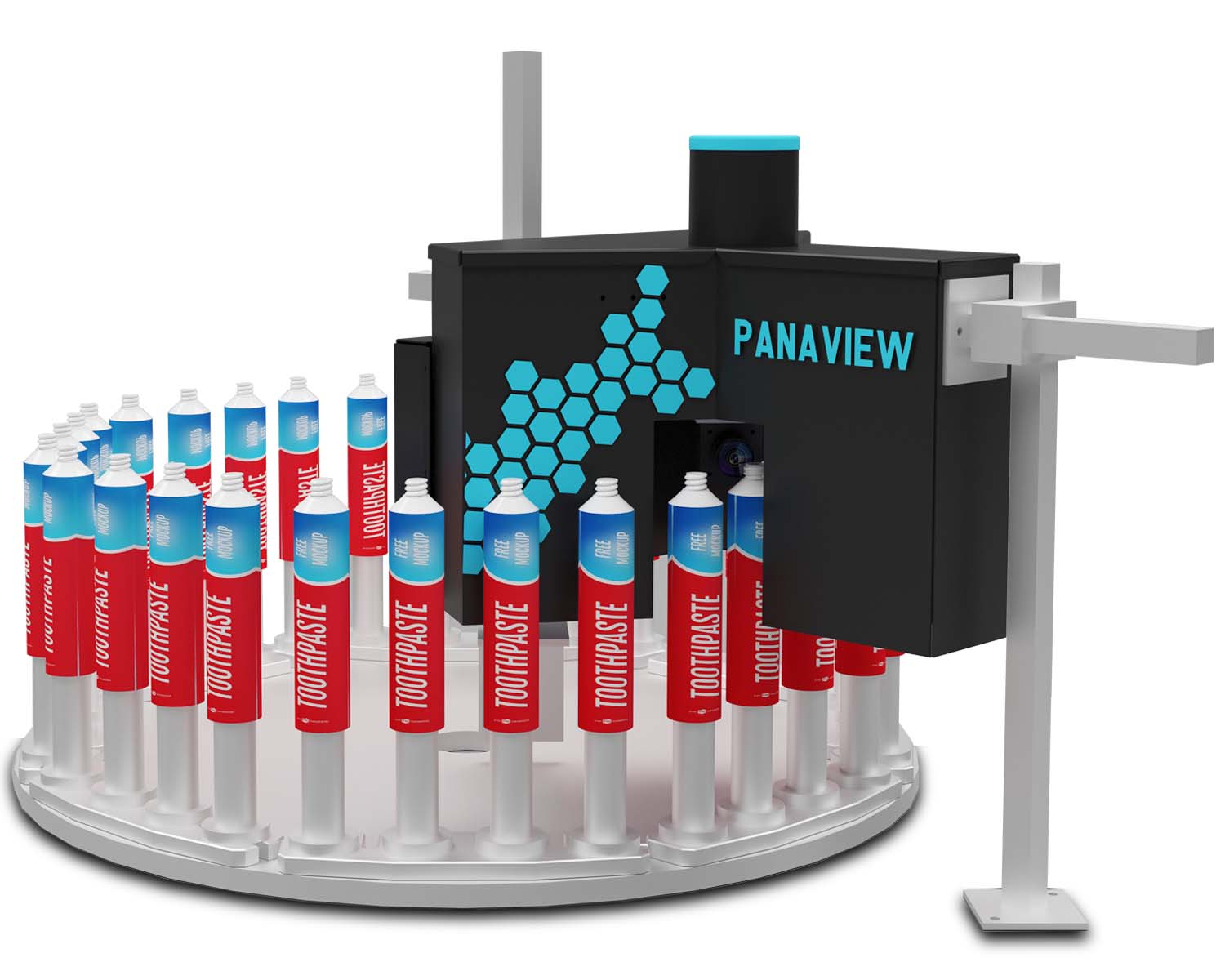

360 Degree Inspection System

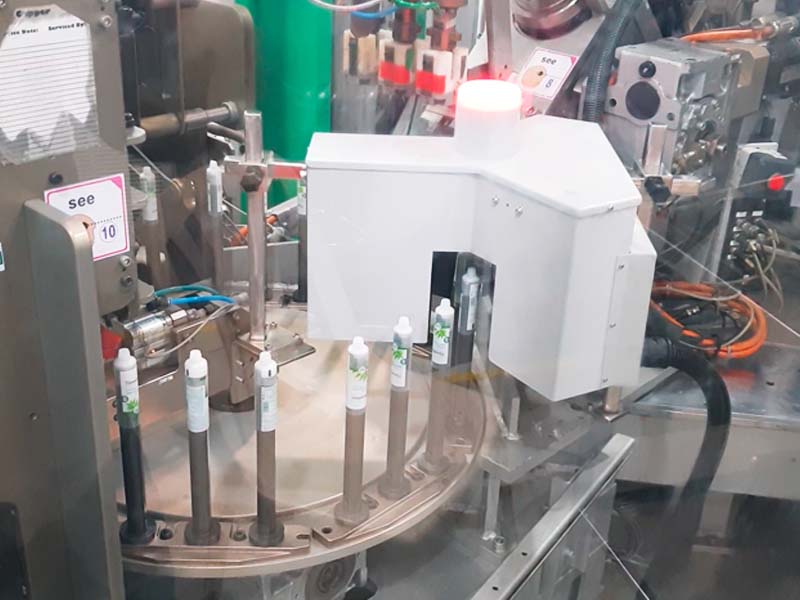

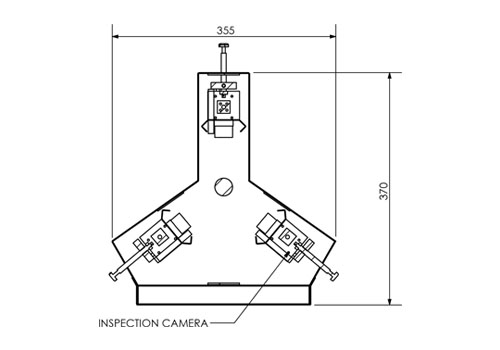

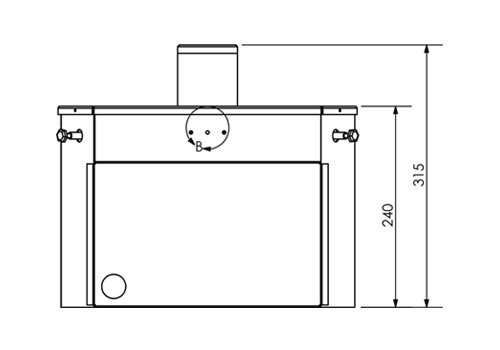

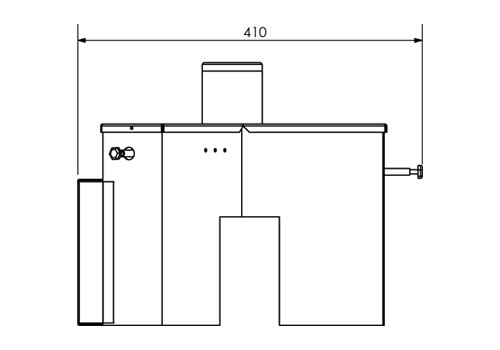

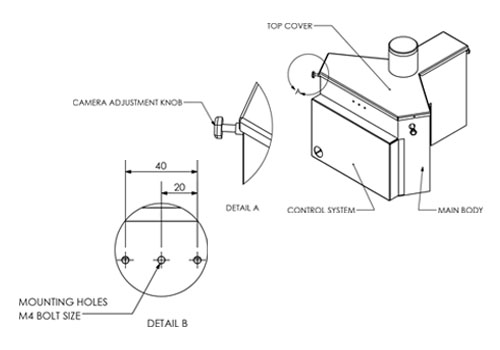

Gridbots PanaView is 360 degree high speed item tube shoulder inspection system. It is fully automated, online system for continuous tube shoulder inspection in 360 degrees. The system can inspect defects at speeds of 600 tubes per minute. The system uses 3 cameras for 360 degree side inspection and 1 camera for top inspection.

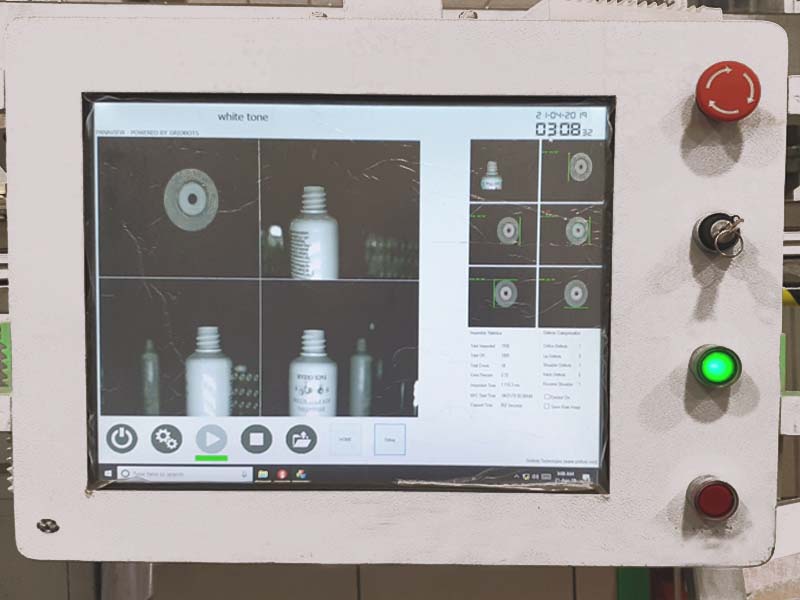

Various defects such as short mould, flashes, reverse shoulder, blocked orifice, partial blocked orifice, neck bend, orifice flash, black particles, color variation, damaged parts, size variations, shrinkages, stretches, missing threads, contamination, foreign particles are inspected with ease.

Easy to use GUI with user, data and recipe management for setting tolerance levels of various defects. System is IOT ready with each machine transmits the inspection data online to local cloud server. Multiple machines send the data to cloud which can be viewed online remotely. Analysis includes total tubes produced, tubes inspected and total tubes defective. Defects are classified in 5 major categories – orifice, lip, shoulder, neck and reverse shoulder.

Alerts and trends are generated in real time regarding the defects. The system can work with any type of tube manufacturing machine such as PACKSYS Global or ASIA. The inspection system is mounted on the available station on the tube manufacturing machine. The rejection system is integrated with the machine to reject the defective tube going into the packer.

360 DEGREE INSPECTION SYSTEM