Seal Inspect

Induction Seal Inspection System

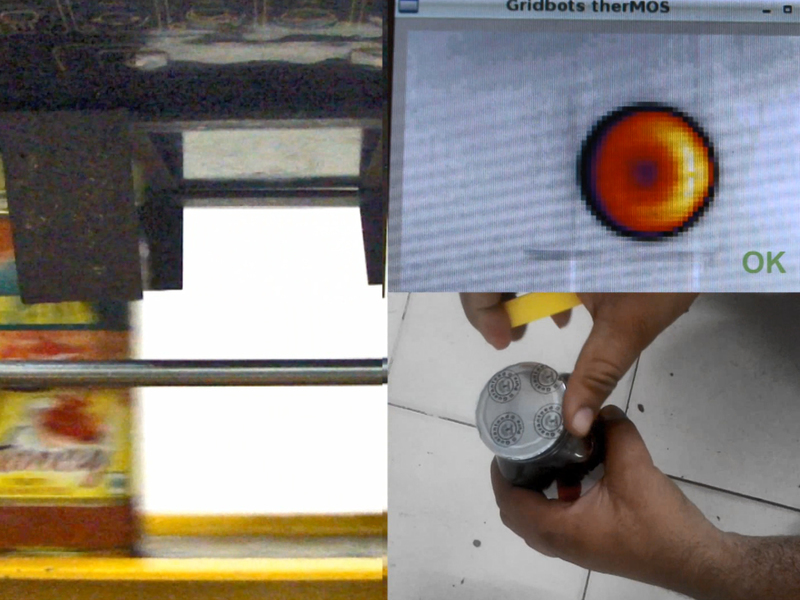

Induction sealing is common bottle sealing process for in Food, FMCG and Pharma industry. The only issue with this sealing process is that you need to monitor the sealing efficiency by putting manual labor just after the bottle capping process. The manual labor randomly picks the bottle, open the cap and check the sealing quality. However this is not foolproof system and this is where Gridbots Induction Seal Inspection System is recommended.

INDUCTION SEAL INSPECTION SYSTEM

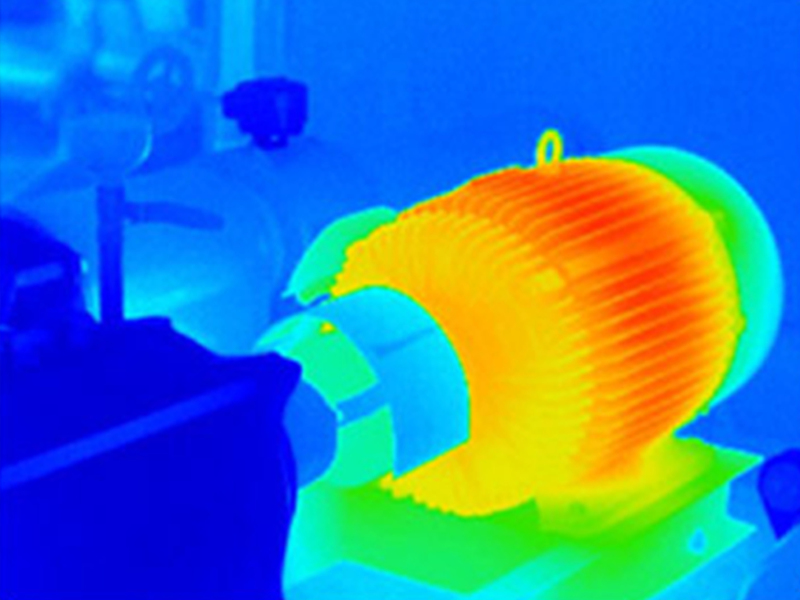

The system uses highly advanced thermal sensors and complex image processing algorithms to determine the induction seal quality without the need of bottle cap opening. It can detect various defects such as Detect critical defects in induction sealing of Jars such as under heating, damaged lip, missing foil, bend foil, over burnt foil etc as shown below.

The system is modular with each module gives 60 BPM inspection speed.