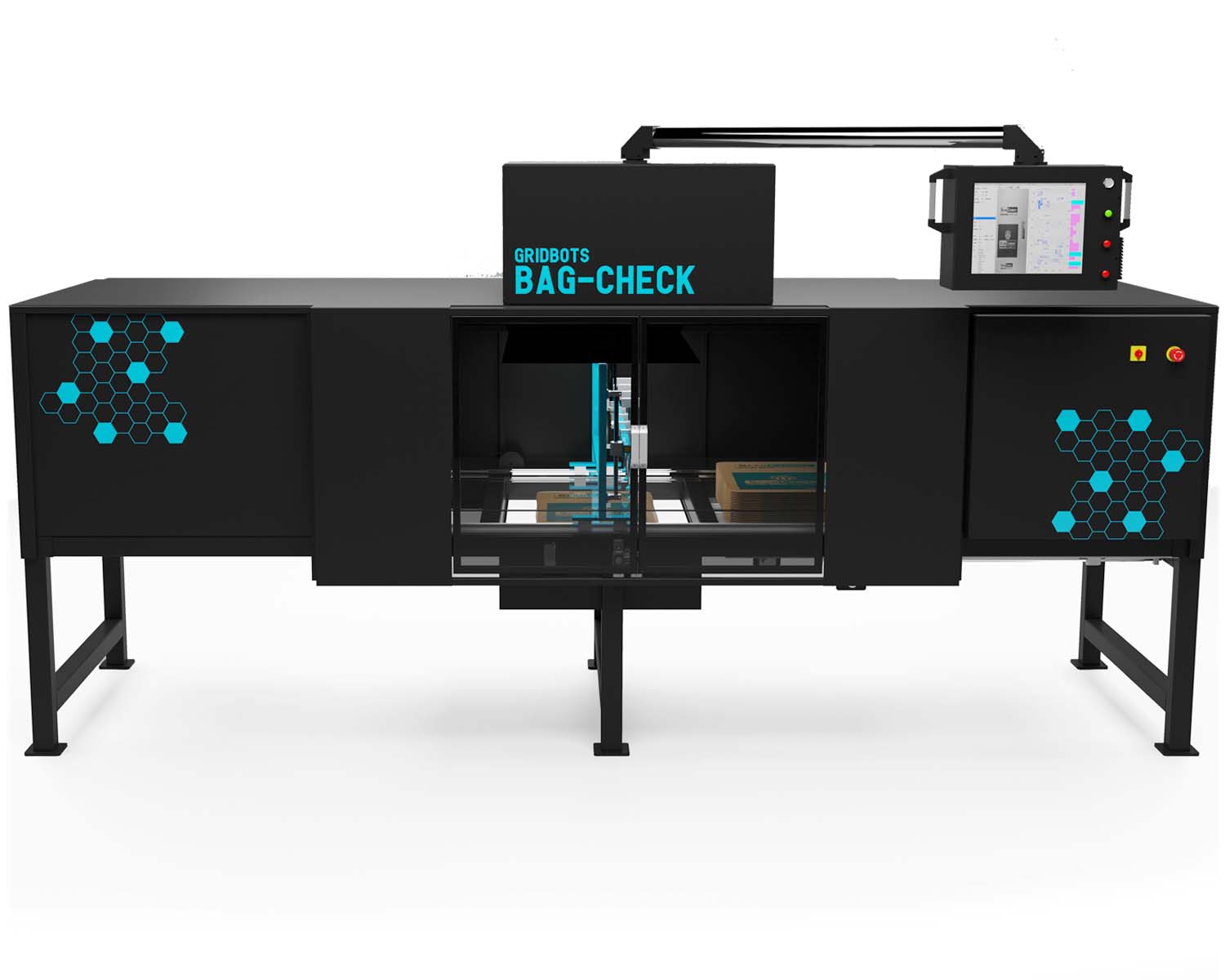

Gridbots BagCheck

Robotic Bag Inspection System

Gridbots Bagcheck is an integrated machine vision solution for small and large woven PP and other fabrick bags.

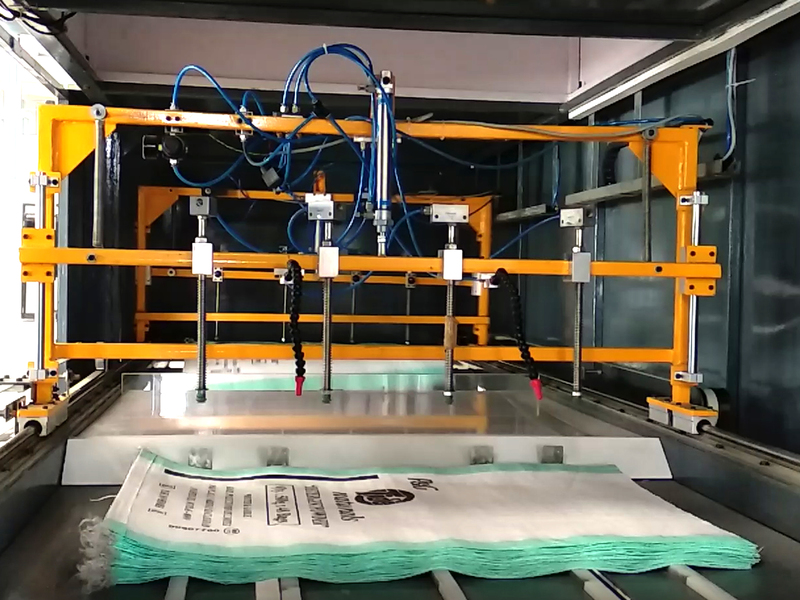

The system automatically checks item for dimensions, surface defects, printing defects and fabric defects using twin high resolution camera's from top and bottom.

It has two linear robots - one for automatic pick and place of bags from a bag stack and bring to the vision inspection table, other robotic arm to pickup bags from inspection table and put in accept or reject stacks. The cycle time is 2 seconds and it can inspect around 30,000-40,000 bags per day.

AUTOMATIC WOVEN BAG INSPECTION SYSTEM