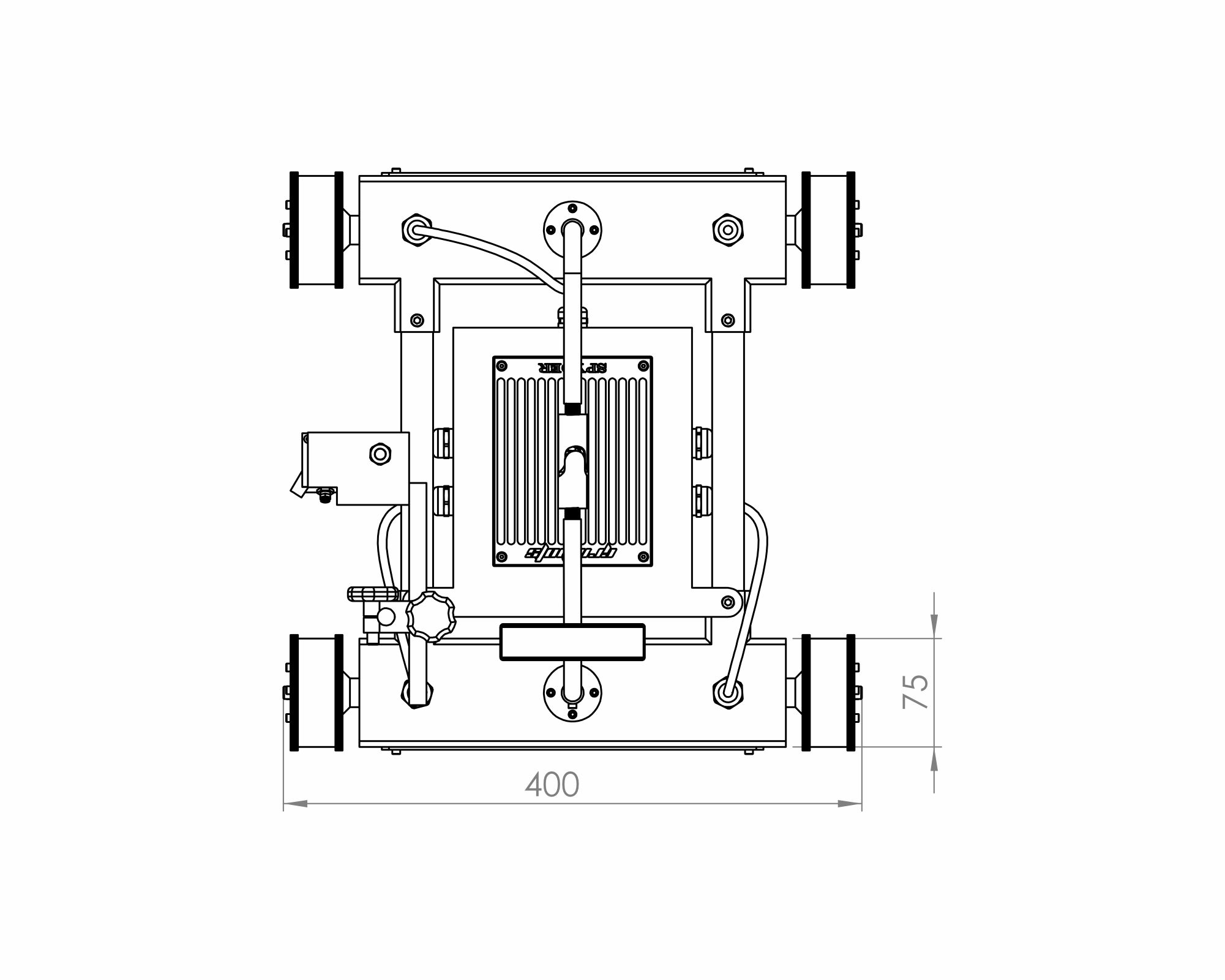

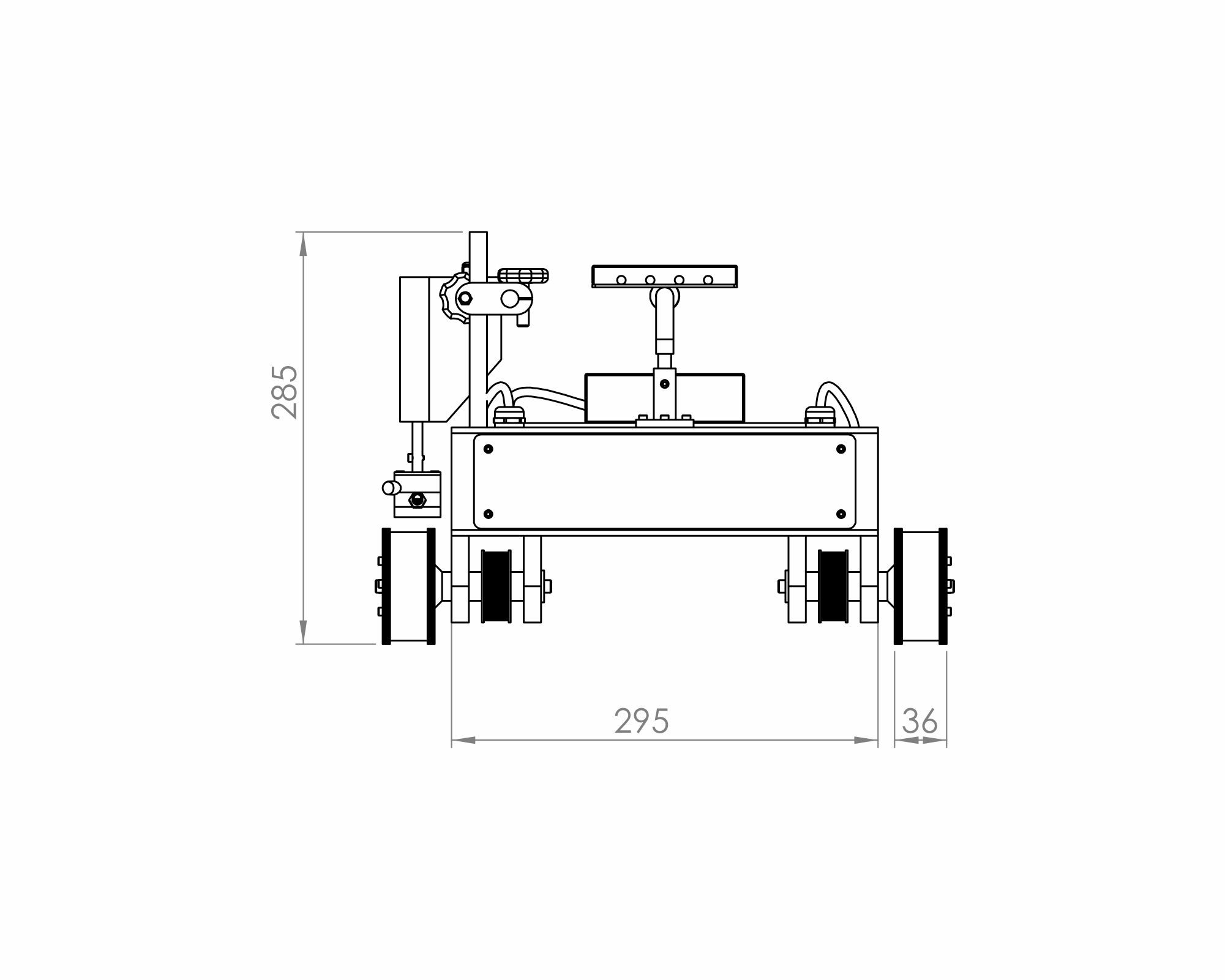

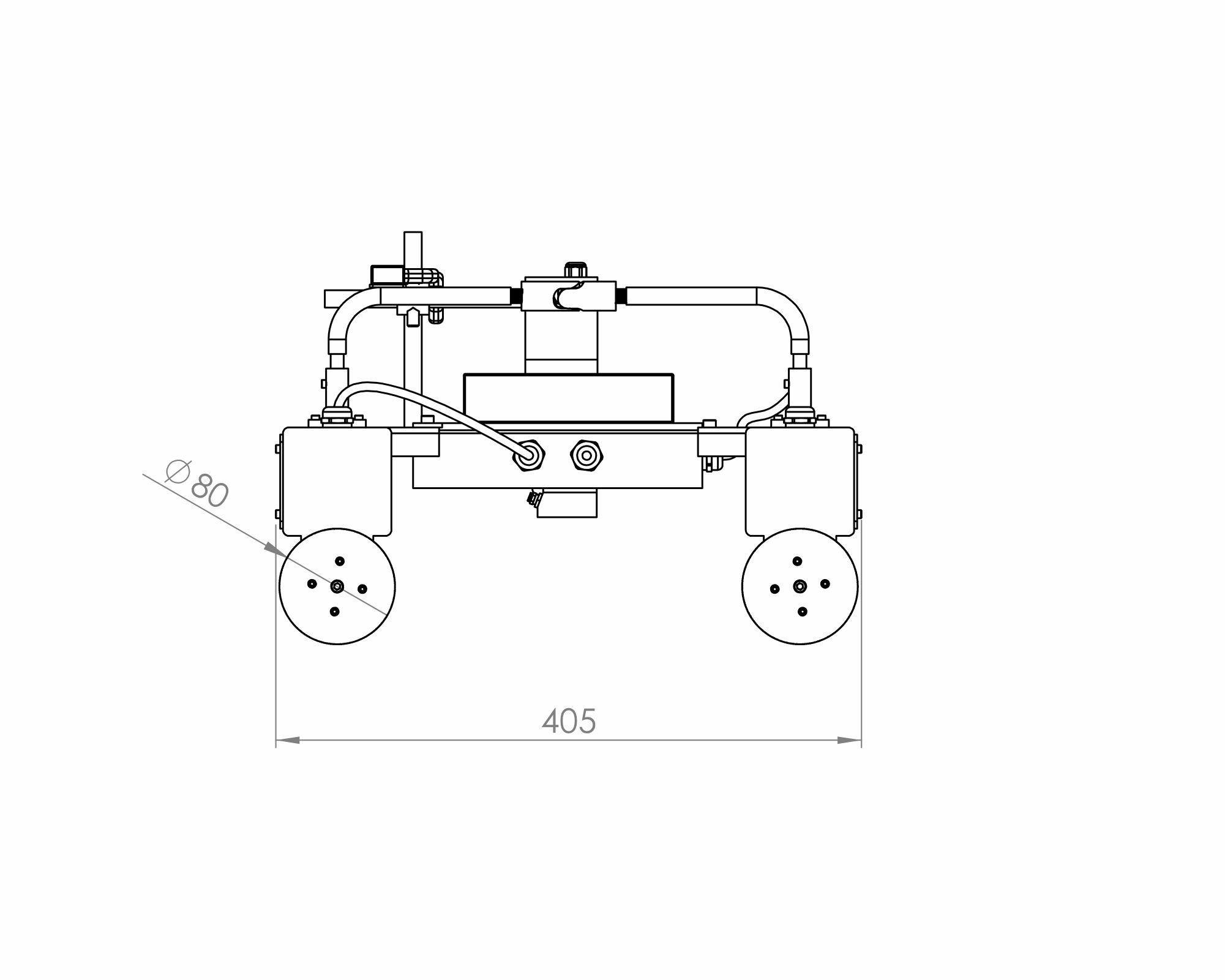

Gridbots Spyder

Pipe Climber Robots

Gridbots Spyder series of robots are desgigned to be used in vertical and inclined pipe inspection and operations jobs.

It has the capabilities to climb almost all kind of magnetic pipe surface with a payload upto 5 kgs in most extreme temperature and surface conditions. The robot can be used for surface inspection, weld inspection, blasting, painting, coating, grinding, lapping or many other operations where it is difficult for a human worker to reach. The robot is ultra light construction from aircraft grade aluminum and high strength magnets to adhere to the surface with active distance compensation force multipliers underneath the body.

The robot is internally powered by strong PMSM geared motors,pedometer and 6 DOF IMU sensor to track the motion in all 6 DOF.It also features distance offset sensor beneath its surface to keep a constant distance maintaned from the surface.

The robot has an array of 10 EMAT/USONIC sensors to measure the tube thickness and report it in real-time to the base computer- where a depth profile of pipes can be composed for later analysis